Variable Data Printing Knowledge Base

Variable Data Printing

Variable data printing (VDP), also known as variable image, or variable information, is an important part of today’s printing industry. VDP is a descendant of digital printing—offering the look and feel of conventional printed material, but with digital capabilities such as convenience, speed, and control. Variable data printing allows industries to go beyond the production of small batch single labels, and instead focus on mass customization that allows for unique, individual, labels to be created in one large batch.

But exactly what is the unique characteristic of variable data printing? And how can it be used in manufacturing today? Let’s discuss these topics as we dive into the topic of variable data printing.

What is variable data printing?

So, what is the variable data printing definition? VDP is a form of on-demand, digital printing that allows you to customize and change elements in each piece printed, without stopping or slowing down the printing cycle. Elements changed could include text, numbers, graphics, images, or colors. Variable data printing is often used in marketing, advertising, and customer relationship management, but it can also be used in manufacturing to create labels or other forms of printed work used for instructions, machinery, or warning signs.

What is variable data printing used for?

Variable data printing is a way to customize mass printing jobs without slowing down the production or stopping the process to change the information on each piece printed.

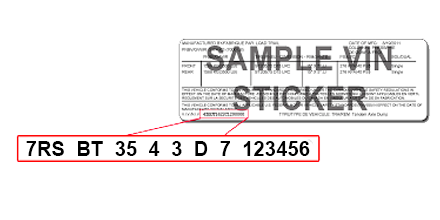

For instance, without variable data printing, to print 60 labels, each with a different vehicle identification number (or VIN), a printer would have to print one label per batch, manually switching out the VIN every print. Not only is this process tedious, but it’s slow and costs the client a significant amount of money. Instead, with variable data printing, this could be done with ease. When VDP is used, each label can be printed consecutively, using data that is pulled from a data source, such as an Excel file, to automatically pull the VIN between each printed label while still keeping the flow steady. The VDP process can be done in the same amount of time as it would take for a printer to print a label with the same VIN across all the labels.

What is the origin of variable data printing?.

Frank Romano, Professor Emeritus at the School of Print Media at Rochester Institute of Technology is widely credited by coining the term variable data printing. He does not explicitly take credit for the origin of the term, but he points to using the term as early as 1969 and he uses it in his book published in 1999 called “Personalized and Database Printing,” which he co-authored with David Broudy.

Although the term variable data printing has been around since the ‘60s, the new and improved variable data printing software is considered cutting edge, enabling it to accomplish faster batches with more customization.

Many modern variable data printing software allows for more enriched content, meaning that you can add in more variable data and elements that can change. Other aspects of modern variable data printing software include rendering overprinted and transparent elements so they are printed correctly or storing and reusing previous print jobs so they can be used again if a client reorders them, eliminating any bottlenecks. Some VDP software also have different authoring program languages for different needs and workflows. Finally some variable printing software integrated with the web for mobile, automated printing jobs.

.

What is the purpose of variable data printing?

The purpose of the VDP is ease, speed, and control. A trusted printing partner will want to solve your problems regarding signage and labeling. Whether it’s keeping your production line on schedule by having your labels accurate and on time, or making sure your internal labeling is precise so you’re following regulations, a variable data printing partner can be the solution you need. Making quality labels that are each unique and can be shipped out all at the same time allows businesses to easily print the necessary, individual labels they need, while saving time and money. Since the process is all automated, it also allows you to know with certainty that the labels will be printed accurately.

Many printing vendors offer pre-checks or samples of labels to make sure all the information and fields populate accurately. The control over this process, making sure that all the information is correctly printed, makes it easier when it comes to having the final prints ready for use.

How does variable data printing work?

A variable data printing machine works by pulling the data and information, such as numbers, images, text, or URLs, from a spreadsheet or dynamic system and inserting them into the file that is being printed. Variable data printing uses the latest technology to efficiently and effectively print the labels you need to comply with regulations or complete your manufacturing processes. After sending data to a printer, via a spreadsheet such as Excel Macro, the printer pulls the information needed for each piece, automatically updating the information from label to label as they are being printed.

What are the types of variable data printing?

Variable data printing is often associated with marketing and advertising. Variable data printing allows marketers and advertisers to personalize their material to their target audiences. Many markets insert the target’s name, address, age, or even hair color right into the piece. Images and graphics are also changed depending on the target’s location or other variation. Pieces that could be printed using variable data printing could be postcards, posters, brochures, flyers, or catalogs.

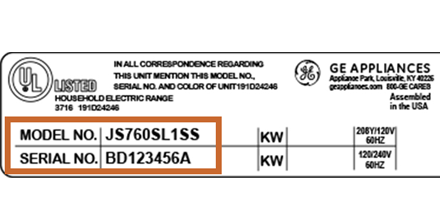

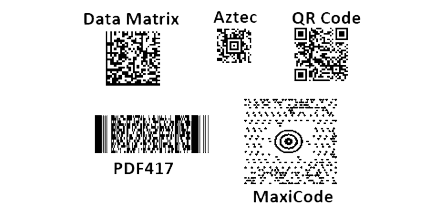

There are also many uses for variable data printing in manufacturing, agriculture, transportation, construction, healthcare, and power equipment companies.Many of these types of companies are required to have labels with specific information printed on them. Labels are often critical to operation and require printing that changes elements, like serial numbers, bar codes, or VINs, from one printed piece to the next.

Here at DuraMark Technologies, we offer variable data printed labels for with unique elements such as:

Linear Barcodes

Serial Numbers

2D Barcodes

VINs

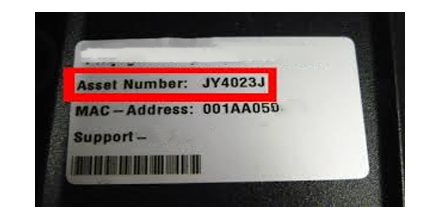

Asset Numbers

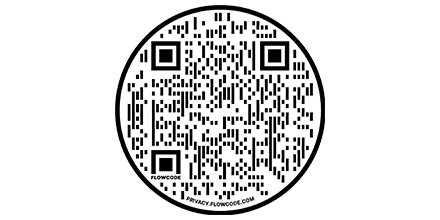

QR Codes

What is an example of variable data printing?

Variable data printing can be used in many ways for your business. Let’s take a look at variable data printing examples.

A construction company needs to label their machinery with asset numbers to signify the company purchasing the equipment they use in production. They have 1,500 machines, each with three areas that need to be labeled with asset numbers. With this variable data printing project, the printer would print a total of 4,500 labels, pulling data from the datasource and changing the asset numbers every third label so there are three identical labels per machine. This would result in 4,500 labels that are in sets of three for the 1,5000 machines.

Another example would be where a manufacturer is implementing new materials for a process and needs 50 QR code labels that employees can scan to get instructions on how to use a specific set of materials. The labels all look the same except for the QR code that needs to be changed on every label. In this variable data printing project, the printer would pull the unique QR code image from a database between every print and change it for every label printed, without stopping the cycle.

A third example can be seen in a company that manufactures cars. At the end of production for each vehicle, a unique VIN label is required to identify the vehicle. In this variable data printing project, the printer would pull the specific VIN from the data data and change the numbers on each consecutive label. Since the car manufacturer constantly produces cars, a quality printing company can save this process and data source so the manufacturer can order new and unique VIN labels when needed, without slowing down production or distribution.

How much do variable data printing jobs cost?

Variable data printing jobs vary in price depending on multiple factors, including size and scope of the items being printed and how much is varied between the pieces. However, many providers will price variable data printing jobs using factors such as:

- The number of variable elements

- The number of items being printed

- The size of the items being printed

- How much color is on the items being printed

- Font

- Bleed

- The type of data source

Since individual, unique labels are essential for manufacturers who have regulations on labeling products, variable data printing can help meet compliance with ease and affordability compared to other options.

The benefits of variable data printing

Today, manufacturers are utilizing variable data printing technology more than ever because of the speed of production and quick turnaround time. Variable data printing helps you to create hundreds or thousands of completely unique QR codes or serial numbers, without having to pay for individual print jobs or receive multiple shipments. Since variable printing doesn’t require each variation to be ordered, printed, and shipped separately, thousands of unique printed pieces can be executed at mass production rates, making individual, specific labels not just simple, but fast.

Choosing a quality variable data printing partener allows you to find real solutions and in turn, see real business outcomes. Here at DuraMark, we focused on four qualities that are benefits to our clients: cost efficiency, quality and durability, customer service, and process improvement.

Cost efficiency

We help our clients reduce costs on every level, from creation to delivery. Our processes help industries become more efficient, eliminate waste, and save money while still receiving an exceptional product.

Quality and Durability

Our flexibility and technology gives clients access to speed and agility compared to other clients. Our four-day turnaround time meets high demands. Our printing process and material is of the highest quality, ensuring that our customers get the most durable product on the market.

Customer service

We emphasize teamwork, partnership, and support for clients. We strive to be the most responsive to solve the problem regarding labeling and decals for our customers.

Process improvement

We are dedicated to improving processes and eliminating errors in production. Our approach to process improvements with unit specific kits and prototyping can help your company meet lean manufacturing goals.

What are the challenges with variable data printing?

When you don’t have the correct labels on your products, your customers will see that your product is non-conforming and your company’s credibility is jeopardized. Even if the parts have the labels in the correct place, a worn label that wasn’t durable enough or a label that didn’t have exactly the correct information on them can ruin a product entirely.

This is also a concern for companies internally. If containers are incorrectly labeled, there might be issues when trying to find the correct product on the plant. If machines are labeled incorrectly, then employees have the potential of being severely injured. Not only is leaning on manual data entry for your variable data printing slow and costly, but it introduces so much room for error. Also, printers that use the incorrect material or ink for printing processes can wreak havoc.

Printing variable data labels with traditional machines, such as traditional screen printing can produce so many challenges. Not only can it be time-consuming and expensive, traditional screen printing results in longer delivery times, so you may not get your labels exactly when you need them. Digital printers can be used to produce variable data labels quickly and affordably, but they sacrifice quality and durability of the labels. Labels printed digitally can wear or fade quickly and won't stand up to the durability test many manufactures require. When printing unique barcodes, serial numbers, or QR codes for manufacturers, the labels must be clear and durable, with lasting adhesion. DuraMark Technologies offers all these qualities in our label printing, because we use the highest-quality printers with the most durable materials and ink. We use commercial digital inkjet printers to print our labels on premium polyester. These labels can withstand the harshest of conditions. Our premium polyester labels have UV blocking laminate and UV protected ink, so they deliver unmatched durability, adhesion, and clarity over the life of your application, no matter the environment.

Best practices in variable data printing

Labels can be worth as much as the part or machine being labeled. Automated and high-speed manufacturing operations have particular requirements when it comes to labeling. Labeling in manufacturing has become just as important as the actual production process. A perfectly good part or machine with the wrong label can be a serious issue.

Although the concept of a variable data printed label is simple—a tag fixed to a part of a package with specific and unique information printed on it—your customers and employees are counting on you to communicate accurately with them about the identity and quantity of the parts or machine you're delivering to them. For many companies, labeling is an integral process to the downstream manufacturing and assembly processes. In the same manner, your employees are counting that every machine they are using is appropriately marked and identified.

Here are a few best practices when it comes to printing and using your variable data labels:

1. Integrate printing time into your sales order, scheduling, and production tracking systems and choose a quality printing partner that delivers orders on time to reduce the risk of mistakes or failing to receive labels shipments.

2. Choose a printing partner that allows you to create and edit labels so your team can adjust information and formats as customer, industry, or regulatory requirements change.

3. Utilize barcode or QR code technology to ensure quick and accurate identification for your machines. Individuals or employees will be able to scan labels with a mobile device to receive the necessary information regarding the product.

4. Always keep a master file of label requirements for your team to reference.

5. Once you receive your printed labels, apply them as quickly as possible to when the process is complete. For labels used on machines that are being manufactured and sold, you want the labels to be placed on the right parts correctly. Waiting to put on labels can result in incorrect placement of labels.

When striving to meet demands, customer expectations, and employee satisfaction, your company can not afford to lose track of stock or wait time waiting for labels that weren’t shipped on time or made incorrectly. Follow the best practices and choose a trusted printing pattern for your labels, minimizing all potential errors in the labeling process.

How to choose the right variable data printing company

Are you treating labeling as a critical aspect of your production process? Considering the specific logic involved with labeling pieces with variable data to comply with regulation requirements or satisfy customers, the company you choose to assure the labels are made correctly and efficiently is vital.

For manufacturers to be successful when labeling their parts, products, containers, and machines, they need a quality printing partner that they can rely on. The printing partner you choose should be based on these key principles:

1. A printing partner should use your variable data efficiently to create the required labels correctly and efficiently. They should be able to reuse this information as needed to correctly create labels as your company needs them, while also being able to change or update the data as needed.

2. A printing partner should be able to work hand-in-hand with your company’s management to minimize costs, save time, and make the labels organized so your team knows what each label is and where they need to be placed.

3. A printing partner that is timely and produces accurate labeling helps ensure that quality is consistent between batches and shipments.

4. When shipping batches, many printing companies like to stick multiple labels sheets in a package, without any organization or instructions. This can create confusion on the production floor for manufacturers. Choose a printing partner that uses a kitting process where labels or decals are printed on a single sheet and come with identification on what the label is and where it goes on the machine or project it belongs to. With product-specific kitting, all decals and labels for a specific product will all be in one place—helping to eliminate time and errors.

DuraMark’s approach to variable data printing creates a stronger partnership

Do you need labels with variable data on a consistent basis? DuraMark creates a strong partnership with our process that will help your company better manage inventory, reduce overhead, and continue timely distribution. We’ll work with your production schedule to ensure prompt delivery, so you have the correct labels at the perfect time.

When sending us information for your labels, you can send the data directly to us via Excel Macro. We will quickly create your customized label with the correct information and to your specifications. After our standard four-day production time, all labels are shipped promptly.

Our labels are made with durable and superior, fade-resistant polyester materials. We want to help you solve your company’s problems, and with our partnership, we will focus on innovation, speed, efficiency, and productivity.

Here at DuraMark, our team works together with you to solve the problem you may have in the variable data printing process. Our company culture encomompases these values:

- Customer satisfaction by giving our customer the best experience possible

- Doing the right thing by acting with integrity

- Having a positive attitude, motivating others, and working hard

- Producing a well-executed and quality product

- Being collaborative team players

- Having the passion to grow and learn

Ready to get started with a trusted printing partner? Contact us today.