Which Printing Method is Right for Your Business

Not all decals are printed the same way. In this email, we would like to explain the differences between three popular printing methods: screen printing, digital printing, and flexographic printing.

Screen Printing:

Screen printing is a traditional printing method that uses a stencil to transfer ink onto a substrate through a mesh screen. It's a versatile printing method that can be used on a variety of materials such as paper, plastic, fabric, and metal. Screen printing is best for high-volume printing jobs that require a solid color or a limited number of colors. Some of the key benefits of screen printing include:

- High-quality and durable prints

- Suitable for printing on a variety of materials

- Cost-effective for high-volume printing runs

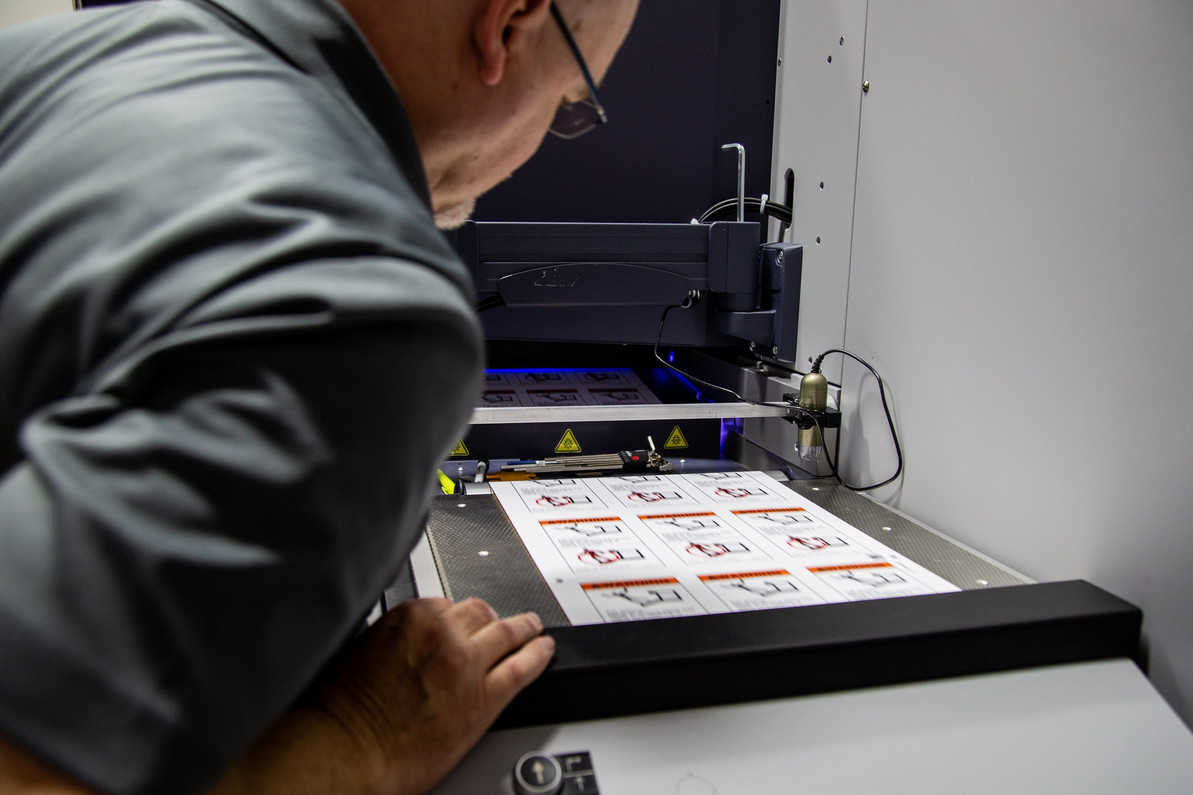

Digital Printing:

Digital printing is a modern printing method that uses digital files to transfer ink onto a substrate. It's a flexible printing method that can produce high-quality prints with complex designs and a wide range of colors. Digital printing is best for printing smaller runs or customized products with variable data. Some of the key benefits of digital printing include:

- Quick turnaround times for small print runs

- High-quality prints with precise color matching

- Suitable for printing on a variety of materials

Flexographic Printing:

Flexographic printing is a printing method that uses flexible printing plates to transfer ink onto a substrate. It's a versatile printing method that can produce high-quality prints with multiple colors and intricate designs. Flexographic printing is best for printing on flexible materials such as paper, film, and plastic. Some of the key benefits of flexographic printing include:

- High-speed printing for large print runs

- Suitable for printing on a variety of flexible materials

- Cost-effective for large print runs

At DuraMark, we offer all three printing methods to ensure that we can meet the specific needs of our clients. Our team of experts can help you choose the best printing method for your project based on the material, design, and quantity of prints you require. We use state-of-the-art equipment and high-quality materials to ensure that your prints look great and last for a long time.

Recent Posts

-

The Power of Product-Specific Kitting for Labels

In today's competitive business landscape, efficient and impactful product labeling plays a vital ro …May 16, 2023 -

Which Label is Best for Heat Resistance

When it comes to labeling products, it's important to consider factors such as durability and heat r …May 12, 2023 -

Buying Custom Safety Labels

Safety labels play a crucial role in ensuring that people remain safe in a variety of environments. …May 11, 2023